"Its a car again!

26/10/09 08:31 Filed in: Duetto | Restoration

The rebuilt 1600cc engine is running in the Duetto! Kathy watched as I started it up and declared "Its a car again!" Well, the paint needs to go on, along with all the trim, but one could certainly drive it down to the grocery store in a pinch

Here is the final product - red powder coated valve cover and black powder coated carb pennum.

Assembling the Duetto, I am continullay amazed that these were built in mass production. So many items are rather tedious to install and align. The secret might be in the sequencing and sub-assembly steps, none of which I am following!

Ocham's Razor suggests that the simplest solution to a problem is probably the correct one. I was muttering that over and over while attempting to start the new engine. It would flutter but not catch. Should not be the carbs! Should not be the ignition, should not be the crank/piston head assembly, etc, etc - all to complicated, must be something simple.... What would be a simple explanation - nope, plenty of gas in the tank - battery secure with good ground and +12v power delivery.

When I took a peak at the rear exhaust pipe to see if there was any clue in the deposits, it jumped out at me: Duh!!!! The end of the pipe was still swaddled in a plastic bag and a layer of duct tape - put there by the media blaster last May!!! Pulled that off and the sweet thing fired up immediatly.

Here is the last major item I had to buy - the forward exhaust section. The exhaust sounds awesome - better than I remember the 1750 sounding. The pipes are all the same save this front section, which needed to be proper for the shorter 1600 head hight. I stayed with the stainless Stebro product to keep it the same, against my displeasure of the $$$. A bit more than two years ago. I must say they do a good job jigging these up, although even those 1 or 2 degrees of error lead to a lot of %$$###!!!! Stainless of those gauges does NOT bend.

Here is a view of the clutch and master brake linkages under the car. I just love the way the mechanicals stand out against the white paint. Now if only it would stay so clean and bright.

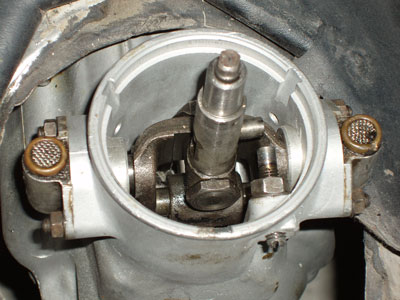

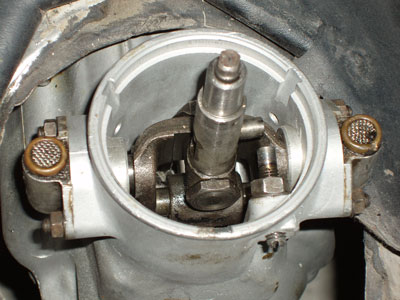

Here is a view down into the transmission shift tower. The shift lever mounts on the rod extending upward. The center "button" is pushed down by the linkage in the shift lever to allow reverse to be selected. The short rod and nut at 4 o'clock keep the arm from comming back (into reverse) unless the button (connected to the little rod protruding out at 3 o-clock) is depressed so as to clear the lock.

One thing I tried this installation is to leave this shift gimbal mechanism out of the tower, and install it after the tranny is in the car. Made getting the engine/tranny a bit easier when dropping it in. That rod sticking up would otherwise drag in the bodywork.

The last major chassis work was to replace the battery tray. The bottom of the tray was heavily corroded. Probably a combination of rust and battery acid. It was spot-weleded into place, so the wleds were removed with a cutter. That was done last spring when the engine bay was prepped for media blasting.

The side shield was still in fine condition, so I thought I would just procure a bottom tray and re-assemble. Finding a tray proved difficult. (geeze, I had 6 months!) I bought one that was perfect - for my 72 GTV... Those folks in Texas had a nice stainless one - but at a staggery price. For the same numbers in euros, I found a complete unit at a German supplier - even had the support brace. In the end, i bought a generic stainless tray for relative peanuts and went about making it fit.

The bottom of the new pan had to be flattened out a bit. The side shield was mig welded on - couldn't get my wimpy spot welder to bite into the stainless. Holes were marked and drilled to attach to fender and support, to allow it to be plug-welded into place.

The mounting area was marked for the weld points, then the paint was ground off and replaced with weld-through primer. Owing to the deep dish of the new tray, the mounting area on the fender will be about 1/3 the number of the original welds, but the result feels really solid. As an upside, there will be less snug-fitting area underneath to collect water and pose a rust issue in the future.

I painted the assembly to match the engine bay. The matching upper battery hold down frame was bought also, and it will be secured with two standard threaded rods. The tray holds the original battery rubber tray perfectly! I am planning on using an Odyssey Drycell Battery (it has a red top...)

Here is the final product - red powder coated valve cover and black powder coated carb pennum.

Assembling the Duetto, I am continullay amazed that these were built in mass production. So many items are rather tedious to install and align. The secret might be in the sequencing and sub-assembly steps, none of which I am following!

Ocham's Razor suggests that the simplest solution to a problem is probably the correct one. I was muttering that over and over while attempting to start the new engine. It would flutter but not catch. Should not be the carbs! Should not be the ignition, should not be the crank/piston head assembly, etc, etc - all to complicated, must be something simple.... What would be a simple explanation - nope, plenty of gas in the tank - battery secure with good ground and +12v power delivery.

When I took a peak at the rear exhaust pipe to see if there was any clue in the deposits, it jumped out at me: Duh!!!! The end of the pipe was still swaddled in a plastic bag and a layer of duct tape - put there by the media blaster last May!!! Pulled that off and the sweet thing fired up immediatly.

Here is the last major item I had to buy - the forward exhaust section. The exhaust sounds awesome - better than I remember the 1750 sounding. The pipes are all the same save this front section, which needed to be proper for the shorter 1600 head hight. I stayed with the stainless Stebro product to keep it the same, against my displeasure of the $$$. A bit more than two years ago. I must say they do a good job jigging these up, although even those 1 or 2 degrees of error lead to a lot of %$$###!!!! Stainless of those gauges does NOT bend.

Here is a view of the clutch and master brake linkages under the car. I just love the way the mechanicals stand out against the white paint. Now if only it would stay so clean and bright.

Here is a view down into the transmission shift tower. The shift lever mounts on the rod extending upward. The center "button" is pushed down by the linkage in the shift lever to allow reverse to be selected. The short rod and nut at 4 o'clock keep the arm from comming back (into reverse) unless the button (connected to the little rod protruding out at 3 o-clock) is depressed so as to clear the lock.

One thing I tried this installation is to leave this shift gimbal mechanism out of the tower, and install it after the tranny is in the car. Made getting the engine/tranny a bit easier when dropping it in. That rod sticking up would otherwise drag in the bodywork.

Battery Tray

The last major chassis work was to replace the battery tray. The bottom of the tray was heavily corroded. Probably a combination of rust and battery acid. It was spot-weleded into place, so the wleds were removed with a cutter. That was done last spring when the engine bay was prepped for media blasting.

The bottom of the new pan had to be flattened out a bit. The side shield was mig welded on - couldn't get my wimpy spot welder to bite into the stainless. Holes were marked and drilled to attach to fender and support, to allow it to be plug-welded into place.

I painted the assembly to match the engine bay. The matching upper battery hold down frame was bought also, and it will be secured with two standard threaded rods. The tray holds the original battery rubber tray perfectly! I am planning on using an Odyssey Drycell Battery (it has a red top...)